|

|

The goal of this workshop is to review some recent advances in the modelling and simulation techniques for the Agro-Food sector, showing Mathematical and Computational tools developed for this purpose. Some of the topics of the workshop will be modelling of heat and mass transfer in foods during cooling and freezing, high-pressure processes, process optimization, identification of food properties, etc. Special emphasis will be placed on industrial applications. |

|

With this letter we want to announce the celebration of the Workshop Modelization and Simulation in Agro Food Technologies. It will take place next November 24th at the Facultad de Matemáticas, Universidad Complutense de Madrid, Spain. Our aim is to join specialists in mathematical models that are of application in the agro-food industry. If you want to attend, please send a message to ja_infante@mat.ucm.es by November 14th. Abstracts of short communications will be received until November 7th. Sincerely, Organizing committee. |

| President:

Ángel Manuel Ramos del Olmo Departamento de Matemática Aplicada Facultad de Ciencias Matemáticas, UCM e-mail: angel@mat.ucm.es |

Pedro D. Sanz Martínez Departamento de Ingeniería Instituto del Frío, CSIC e-mail: psanz@if.csic.es |

|

Facultad de Ciencias Matemáticas Universidad Complutense de Madrid |

| Title Heat and Mass Transfer modelling in High-Pressure Food Processing |

| Authors P. D. Sanz, L. Otero, Á. M. Ramos, C. de Elvira, J. S. Torrecilla |

| Abstract |

| Title Influence of High Hydrostatic Pressure on Thermofuiddynamics of Pressurized Food |

| Authors W. Kowalczyk, A. Delgado |

| Abstract |

| Title Computer Simulation of Ice Cream Solidification |

| Authors J. Aldazábal, A. Martín-Meizoso, J. M. Martínez-Esnaola, R. Farr |

| Abstract |

| Title Multiscale modelling of transport phenomena in fruits |

| Authors Pieter Verboven, Ho Quang Tri, Hibru Mebatsion, Trung Anh Nguyen, Fernando Mendoza, Bart Nicolaï |

| Abstract |

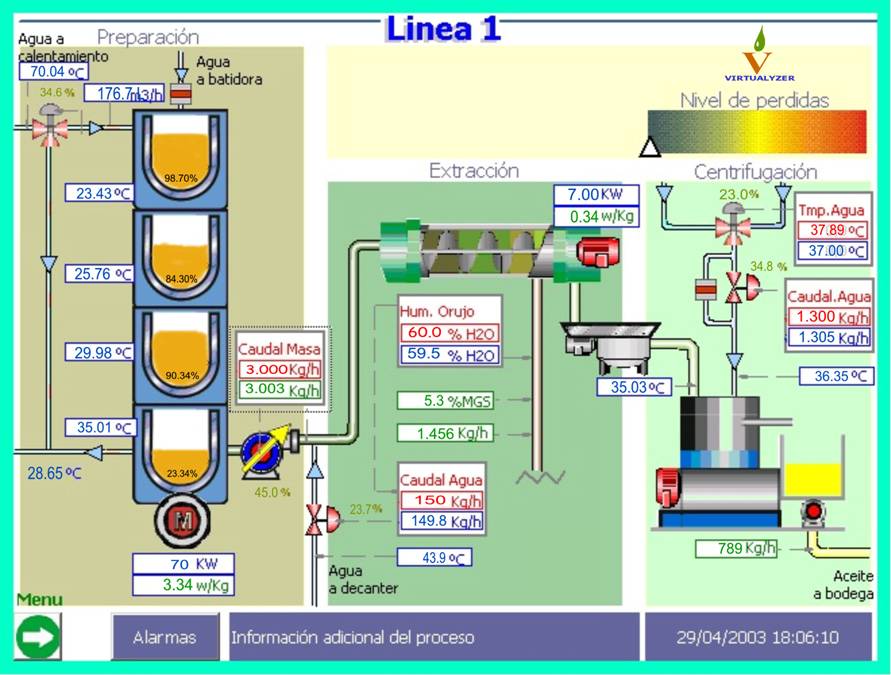

| Title Modeling and Control of the olive oil extraction process |

| Author C. Bordons |

| Abstract |

| Title Modeling the risk of entrance of Foot-and-mouth disease (FMD) in Spain |

| Authors J. M. Sánchez-Vizcaíno, B. Martínez, M. Martínez |

| Abstract |

| Title Travelling wave solutions for a model of a fungal disease of the vine |

| Authors J. B. Burie, A. Calonnec, A. Ducrot |

| Abstract |

| Title Inverse Problems Arising in the Modelling of Food Processes |

| Authors A. Fraguela, J. A. Infante, Á. M. Ramos, J. M. Rey |

| Abstract |

|

Instituto de Matemática Interdisciplinar (UCM) |

|

Departamento

de Matemática Aplicada (UCM)

Página web: http://www.mat.ucm.es/deptos/ma |

|

Espuña

Página web: http://www.tequila-bcn.com/clientes/espuna/esp/produccion_04.htm |

|

|

The MathWorks

Página web: http://www.mathworks.com |

|

|

|

Speaker Dr. Javier Aldazábal Centro de Estudios e Investigaciones Técnicas de Gipuzkoa (CEIT), Spain Abstract This work proposes three different models to simulate the evolution of ice cream microstructure during the manufacturing process. The simulated process corresponds to the solidification in the blast freezer of ice seeds that have been generated in the barrel freezer. All these models are implemented in several computer codes to study their behaviours and predictions. The first model developed here works with an analytical description of the microstructure. It considers the ice particles as spheres. Their evolution is simulated by increasing the size of particles and controlling the dihedral angles that appear among them. The second model proposed is based on the Monte Carlo technique. This model simulates the evolution of a discretized version of the microstructure obtained from the barrel freezer. It includes the sugar concentration in the matrix and its diffusion. The last model is deterministic. It works with a voxelised version of the initial microstructure. The evolution of the microstructure is simulated by solidifying isotropic ice layers surrounding initial solid particles. These layers are grown considering the sugar concentration in the liquid-matrix. This method is able to quantitatively relate the simulated and real time. |

|

Speaker Carlos Bordons Universidad de Sevilla, Spain Abstract The automatic control of the extraction of oil out of olives is still an open field, since many installations are usually operated in manual mode. As olive oil mills are becoming bigger the chances for automation are increasing, therefore it is important to acquire the necessary knowledge of the process behaviour in order to design the appropriate control strategies. This talk deals about some issues related to the modelling and automatic control of olive oil mills. After a brief review of the state of the art in automatic control of oil mills, two main topics are addressed: measurements of crucial variables and automatic control of olive oil yield. Related to the first topic, the concept of soft sensor is introduced and it is shown how it can be used in the olive oil elaboration process. In an olive oil mill, soft sensors measure variables that in other case should come either from laboratory analysis with large processing delays or from very expensive and difficult to use on-line analyzers. The introduction of these sensors in the olive oil industry can help to increase the degree of automation in the elaboration process. The sensors have been devised based upon artificial Neural Networks (NN) and have been successfully tested on a real mill. A solution to the integrated control of the mill is also presented, where a predictive strategy is used to optimize oil yield while keeping quality standards. The talk also shows the application problems that arise when implementing advanced controllers in an industrial control system with low computational capabilities. The talk will also deal with the main issues related to integration and will show some results of the application of advanced control techniques to an actual olive oil mill. The application of the proposed strategies has shown that great benefits can be obtained both in oil yield and extraction performance. |

|

Speaker Dr. Jean-Baptiste Burie Université de Bordeaux, France Abstract Powdery mildew, caused by the fungus Uncinula necator, is the most economically important and widespread disease of grapevines. A better knowledge of its propagation mechanisms could help to improve the treatment strategies. In this talk, we will consider two mathematical models describing the epidemic at the vineyard scale. They both include reaction-diffusion equations that modelize the dispersal in the vineyard of the spores produced by the fungus. The evolution of the fungus is either modelized by a delayed differential equation (first model, Zawolek & Zadoks), or by a set of ODEs of SEIR-type (second model). Both models include the main biological characteristics of the disease: multiple ranges for spores dispersal, a latent and an infective stage for the fungus. We will prove existence and unicity (up to translations) of 1D travelling waves for both models if the speed of the travelling wave is larger than some minimal speed c*. A formula for the computation of the speed in terms of the various parameters is derived. Numerical simulations confirm the existence of a travelling wave with a speed equal to the minimum speed c*. Replacing the various biological parameters of the model with realistic estimations, we find that there is a good match between c*and the velocity of the epidemic observed by the biologists on the field. We will also study the qualitative dependence on the biological parameters of the velocity c*. We will finally give some computation results in 2D that show the role of the row structure of the vineyards on the spread of the epidemics. |

|

Speaker Dr. Andrés Fraguela Benemérita Universidad Autónoma de Puebla, México Abstract In our talk we propose a stable method for the identification of the diffusion coefficient in a mathematical model that describe the phenomena of heat transfer taking place during the high-pressure treatment of foods. In a simple version of the model we solve an inverse problem for the identification of a pressure depending diffusion coefficient in a boundary value problem of parabolic type starting from measurements of the temperature at a given location of the considered spatial domain during certain interval of time.The pressure dependence of the diffusion coefficient is the main complication in the solution of this inverse problem. |

|

Speaker Dr. Wojciech KowalczykUniversity Erlangen-Nürnberg, Germany Abstract The treatment of food with high hydrostatic pressure (HHP) up to 10.000 bars allows an increase of food quality and a diversification of available products. Both experimental and numerical results show that HHP influences significantly fluid flow phenomena occurring in autoclaves. In the current contribution, heat and momentum transfer during high pressure treatment of liquid substances is discussed. In order to characterise the thermofluiddynamics in high pressure chambers, the dimensional analysis of the governing equations is carried out. Both cases with free and with forced convection as well as examples accompanied by phase transitions are considered. The dependency of convective and diffusive heat transfer on temperature and pressure is presented. Additionally, the heat and momentum transfer in high viscous media and chambers with different characteristic length is analysed. |

|

Speaker Dr. J. M. Sánchez-Vizcaíno Universidad Complutense de Madrid, Spain Abstract Foot-and-mouth disease (FMD) is a highly infectious animal disease which affects many species of cloven-hoofed animals and causes important economic loses. Although FMD was successfully eradicated in the European Union in 1992, occasional incursions have been occurred being the most important in 2001, where United Kingdom (UK), Ireland, France and Netherlands were affected. In order to assess the risk of FMD introduction in Spain we have developed a stochastic model which includes all the potential routes of the disease entrance. Our objective was to determine the overall risk of FMD introduction in Spain, the provinces with more risk and the most probable routes of entrance. In this lecture we will describe the considered scenarios in order to understand the sequence of events in time and the interactions among them. The model includes parameters related with the virus, susceptible animals, high risk materials and the probability of exposure and contact. Probability distributions were used for uncertain variables and stochastic effects were obtained using the Monte Carlo simulation (@Risk). The model not only provides the high risk Provinces and the most probable routes of entrance, but also a way to quantify the effectiveness of a control measures implementation. This information can be used to increase the surveillance and control measures in the critical points to reduce as much as possible the probability of introduction of the FMD into the country. |

|

Speaker Dr. Pedro D. Sanz CSIC, Spain Abstract High-pressure processing is an expanding technology that is being successfully introduced in the food industry mainly as a preservation method to control the microbiologic and enzymatic activities in food (Torres and Velazquez, 2005). Another promising application of high-pressure technology, nowadays unexploited but under active research, includes processes involving phase transitions: high-pressure freezing and thawing. Pressure allows the displacement along the phase diagram of water and different kinds of high-pressure freezing and thawing processes can be performed (Urrutia Benet et al., 2004). Among them, high-pressure assisted freezing has a special interest in that it allows obtaining different ice polymorphs depending on the pressure level at which the freezing process has been developed. All ice polymorphs different than ice I are denser than liquid water; therefore, a decrease in volume occurs during the phase transition and low damage is caused to the sample structure (Molina-García et al., 2004; Luscher et al., 2005). In this study an overview of the fundamental, current and future applications of the high pressure is presented. Also a mathematical model of the behaviour of thermophysical properties is presented as well as other mathematical model is described to account for the phenomena of heat and mass transfer taking place during pressurization of a food model. High-pressure experiments were carried out in agar gel samples. During all the experiments, the temperature evolution in the centre and in the surface of the samples were recorded. The mathematical model took into account the free convection that arises in the pressure medium after compression because it has been shown that it affects the thermal evolution of the processed food in a significant way (Otero et al., 2006). Simulations made with the finite element method showed good agreement between experimental and predicted temperature profiles for all the processes studied. Modelling of high-pressure processing is important for the optimization of these new processes and their general implantation in the food industry. Also it is presented a numerical model to simulate Pressure-Shift Freezing processes in a tubular reactor designed to work in a semi-continuous mode on an industrial scale. The model will make possible to optimize different parameters such as the length of the pressure vessel and the displacement rate of the sample. |

|

Speaker Dr. Pieter Verboven Katholieke Universiteit Leuven, Belgium Abstract Transport of gasses and moisture are crucial for maintaining fruit quality during and after storage. These phenomena have been studied and modelled by assuming the product to be composed of different continuous materials (cuticle, outer cortex, inner cortex, vascular tissue). The model parameters, such as the mass diffusion coefficients of the tissue, should however be considered as apparent material parameters which incorporate both actual physical constants such as the properties of water and air but also the microscale geometry of the tissue and the intracellular space. The relationship between the macroscopic apparent properties and the microscopic features is not understood well to date. As a consequence, the available continuum models have a limited range of validity. A multiscale modelling approach is more appropriate than a macroscopic continuum modelling approach to understand the relative importance of microscopic features on the overall behaviour of the biological product. In the other direction, multiscale models will assist the determination of microscopic triggers for internal damage as a consequence of macroscopic environmental changes. Multiscale models are basically a hierarchy of submodels which describe the behaviour at different spatial scales in such a way that the submodels are interconnected. This paper will reveiw the recent advances made in this field. |

|